Quality Testing / Assurance

Rowe Dynamics Inc. provides quality testing assurance which confirm that dimensional specifications and tolerances are met during the parts manufacturing and assembly processes. Inspections are performed using our state-of-art Mitutoyo Crysta Apex C 574 Coordinate Measuring Machine and Deltronic DH216 16" Horizontal Bench-Top Comparator System.

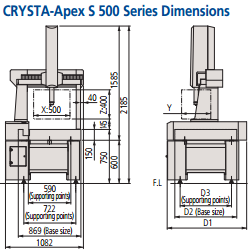

Mitutoyo Crysta Apex C 574 Coordinate Measuring Machine

The Crysta-Apex S 574 is a high-accuracy CNC coordinate measuring machine that guarantees a maximum permissible error of *E0,MPE = (1.7+3L/1000)μm. Comparing the Crysta-Apex S 574 with CMMs offering *E0,MPE of approximately (2.5+4L/1000)µm where a required tolerance on a dimension is ±0.02 mm, then the measuring machine uncertainty should be no more than one-fifth (ideally one-tenth) of that, i.e. 4μm. This means that with a general-purpose CMM, when the measured length exceeds 14.8”(375mm), machine uncertainty exceeds one-fifth of the dimension tolerance in this case. In contrast, the Crysta-Apex S 574 measurement uncertainty remains within one-fifth of the dimension tolerance up to 30.2” (766mm). The higher accuracy specification of the Crysta-Apex S 574 therefore gives it more than double the effective measuring range in terms of accuracy-guarantee capability in this case.

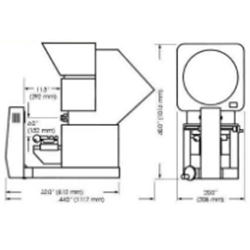

Deltronic DH216 Horizontal Optical Comparator

We have chosen a leader in the field of optical comparators with Deltronic and the powerful DH216. Deltronic has provided us with a solution for countless applications. Our optical comparator lets us set the standard for quality, dependability, and value. Our complete line up of quality control equipment offers the flexibility to accommodate our customers needs.

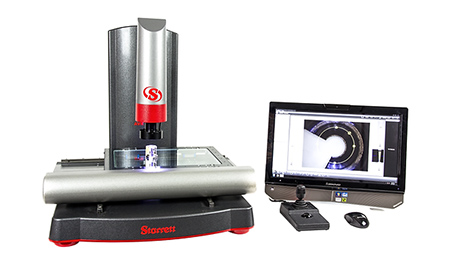

AVR 300 VERTICAL BENCHTOP VISION SYSTEM

The AVR CNC Automatic Vision Metrology Systems are ideal for repetitive measurements and automatic comparison to CAD files. Systems are available with interchangeable telecentric or dedicated zoom lenses for micron-level resolution and accurate field-of-view (FOV) measurements. Learn More.

SCALABLE DATA ACQUISITION, MANAGEMENT & ANALYSIS

Mitutoyo has been developing MeasurLink and serving manufacturing quality programs for more than twenty years. It represents the design input of industry experts and thousands of manufacturers across the globe. It is quality inspection, management and analysis software built on a technology platform for the most robust performance and reliability. Learn More.

Quality Testing Assurance Service Area

Rowe Dynamics Inc. can provide Contract Manufacturing Services to organizations throughout the U.S. and the World.

Benefits of Rowe Quality Test Assurance

- Increased Quality - improves on time delivery reliability and increases production output with fewer defects.

- Increased Efficiency - proper project management allows us to ensure our competitive edge and keeps our customers happy.

- Increased Responsiveness - streamlined processes making better products and solutions for our customers.