Reverse Engineering

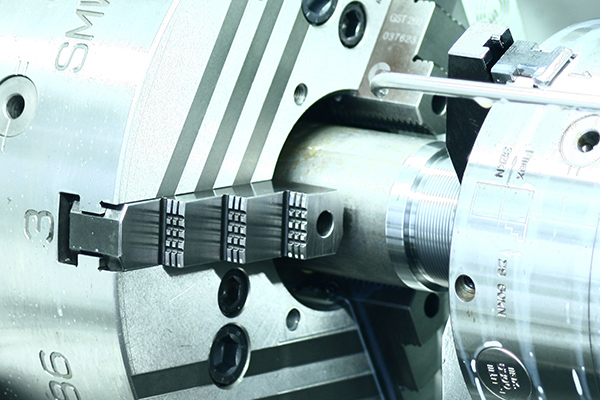

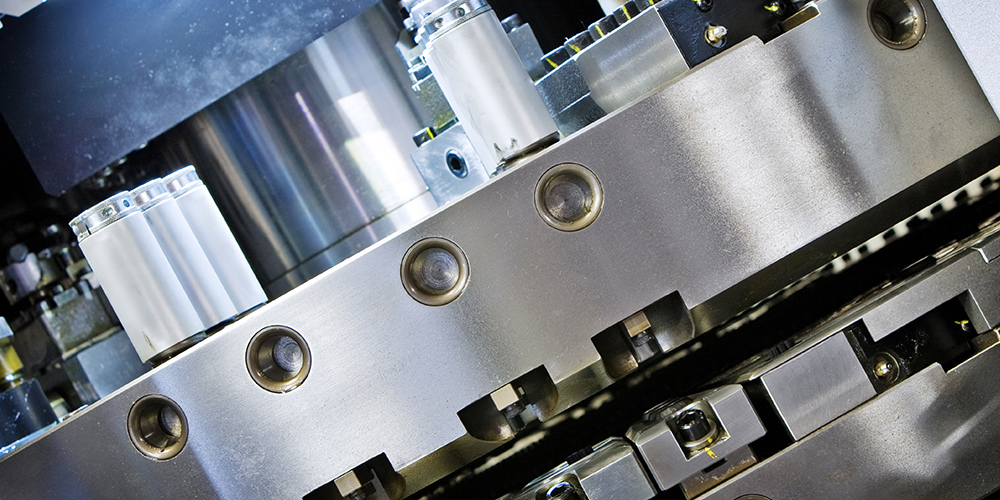

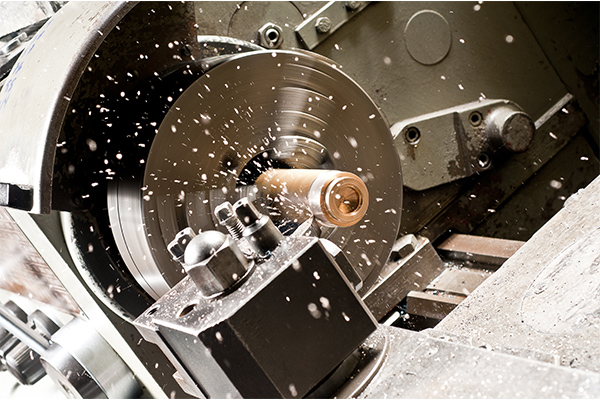

Rowe Dynamics Inc. offers reverse engineering services with unsurpassed expertise for accurately obtaining the geometries and surface characteristics of any size component part and providing you with an analysis of its structure, function, and operation. Our engineers utilize the most precise state of the art equipment available, including laser scanners, machine probes, and delicate manual instrumentation, to create 3D CAD models that capture an object's original design with pin-point precision. We create SolidWorks models that can be used for applications such as dimensional inspections, recreating obsolete and worn parts, or documenting shop floor changes to original drawings.

About Our Reverse Engineering

Conducted in our ISO 9001:2008 certified lab, our reverse engineering services will provide you with a full set of detailed prints along with the 3D CAD models. When required, our manufacturing facility will machine the part in whatever quantity you desire. We have experience in many industries, from aerospace and automotive to machinery, military, and the arts. We take pride in having an engineering team that is knowledgeable, helpful, and completely customer-focused. For more information about how our reverse engineering services can help you with your next project, contact us today.

Reverse Engineering Service Area

Rowe Dynamics Inc. can provide Contract Manufacturing Services to organizations throughout the U.S. and the World.

Benefits of Rowe Reverse Engineering

- Increased Quality - improves on time delivery reliability and increases production output with fewer defects reducing cost.

- Increased Efficiency - proper project management allows us to ensure our competitive edge and reducing cost.

- Increased Responsiveness - streamlined processes making better products and solutions for our customers reducing cost.

Reverse Engineering Capabilities

REVERSE ENGINEERING CAPABILITIES

- Consulting

- Software Models

- Dimensional Inspection

- Recreation of obsolete parts

- Research & Development

- Digital enlargements

- 3D Digitizing

MAIN CAPABILITIES

- Laser Scanners

- Machine Probes

- Manual Measurement Instruments

SOFTWARE

- Solid Works

FILE FORMATS OUTPUTTED

- IGES

- STL

- SolidWorks (SLDPRT)

- Parasolid

- STEP

EQUIPMENT

- Touch Probes

- Machine Probes

- Laser Scanners

- Manual Measurement Instruments

DELIVERABLES TO THE CUSTOMER

- Full set of Detailed prints

- Full 3D CAD model

- Machined parts